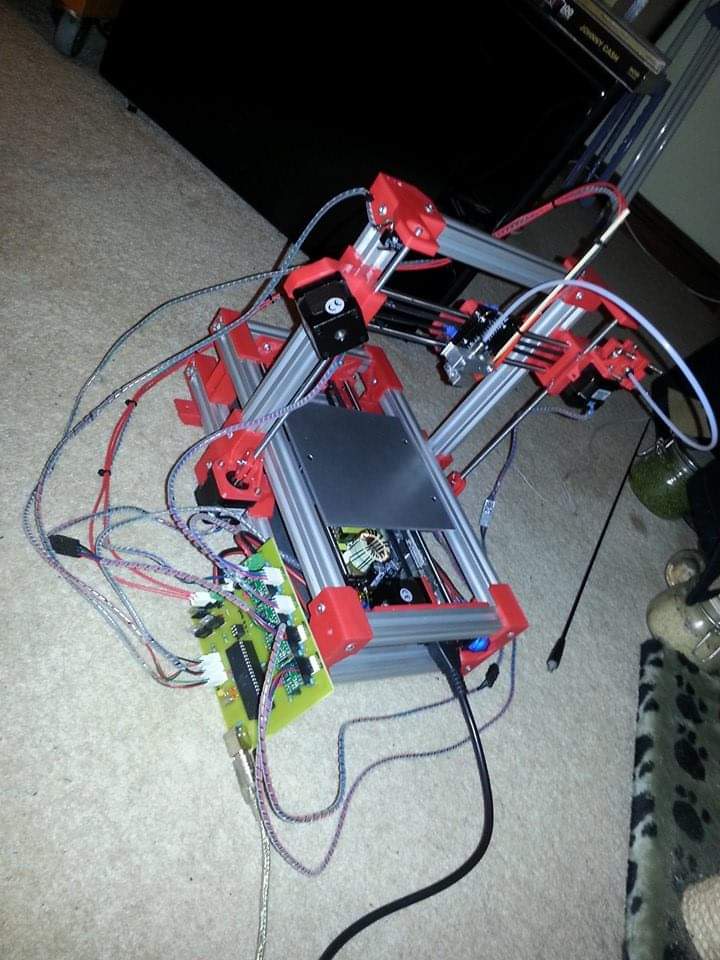

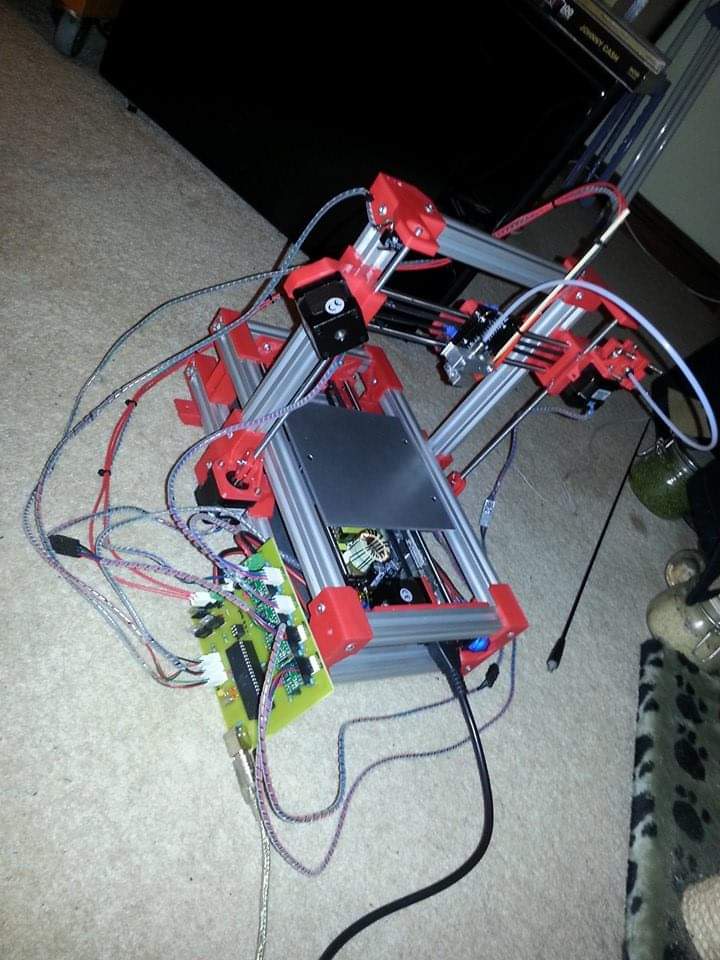

2013 was a busy year for me. Having got married the year before, I decided that it would be a good year to make a 3D printer. After investigating many RepRap projects, I settled on FoldaRap. This was on the basis that it folds away, so it wouldn’t take up too much space in our small house when it’s not in use.

Building a 3D printer looks quite a daunting task, but with some help from friends who had walked this path already, it got easier.

Having settled on the design, I got some help printing the plastic components on his Mendel90, and given his connection to a local laser cutting company, he also produced some laser cut aluminium sheets for parts of the frame.

I’d spent some time in 2012 getting familiar with PCB printing techniques, and I applied this new found knowledge to produce my own controller based on the RepRap Gen7 electronics. This is largely based on the popular ATMega range found in Arduino

Printing with ABS comes with some challenges, and a heat bed is one of the primary requirements. Choosing a smaller 3D printer brought some other challenge; as this was not one of the “standard” sizes, there was no off the shelf part heat bed. Having got hold of some photoresist, I experimented with my own heated bed PCB

Leave a Reply

You must be logged in to post a comment.