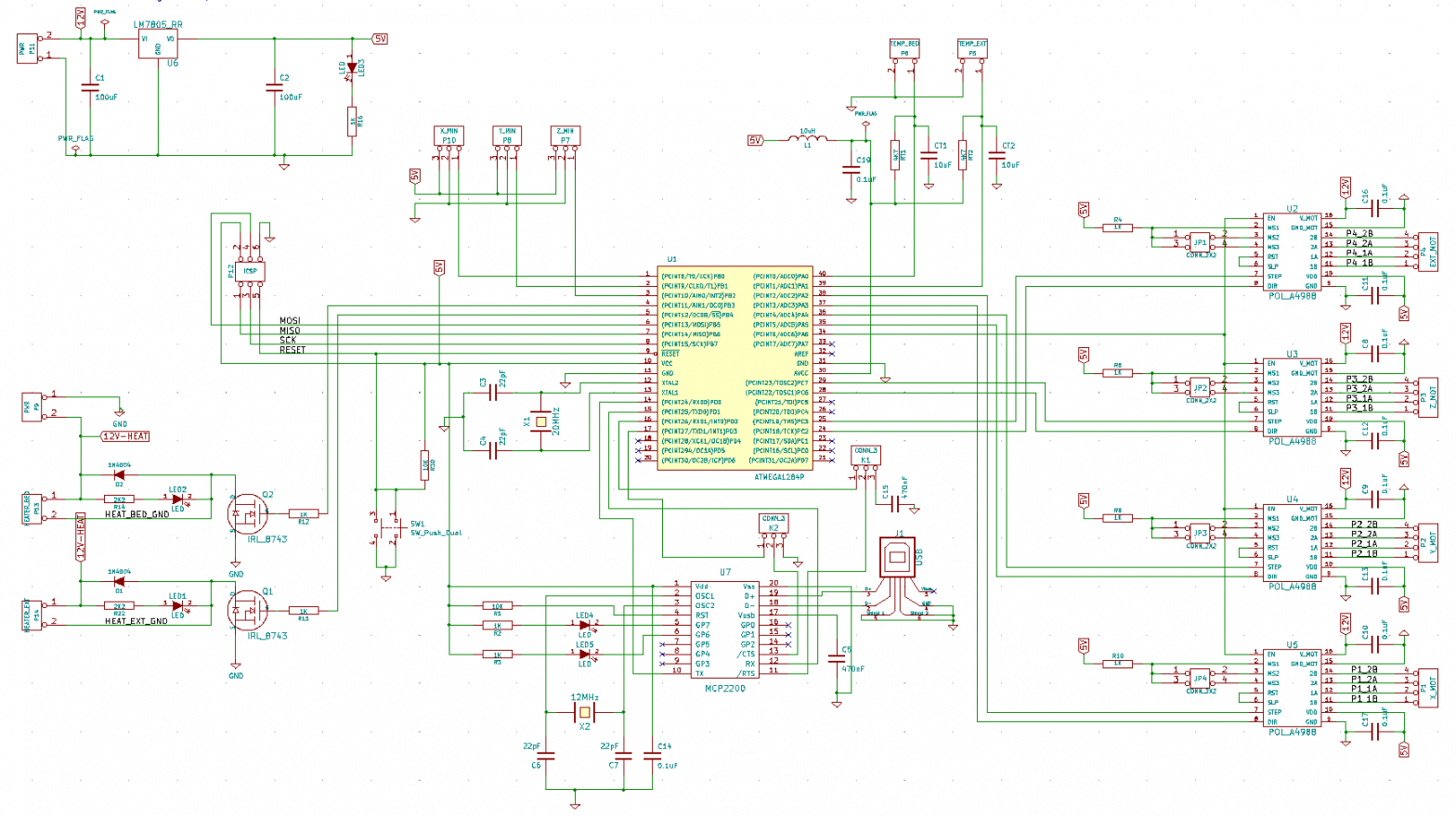

Traumflug created a very robust setup with the Gen7 electronics, and I wanted to make use of that step up for my own project. I had a small problem with it though – all of this was based around an ATX power supply, and I wasn’t using one of them. And it was using a different CAD package to the one I was familiar with (KiCad)

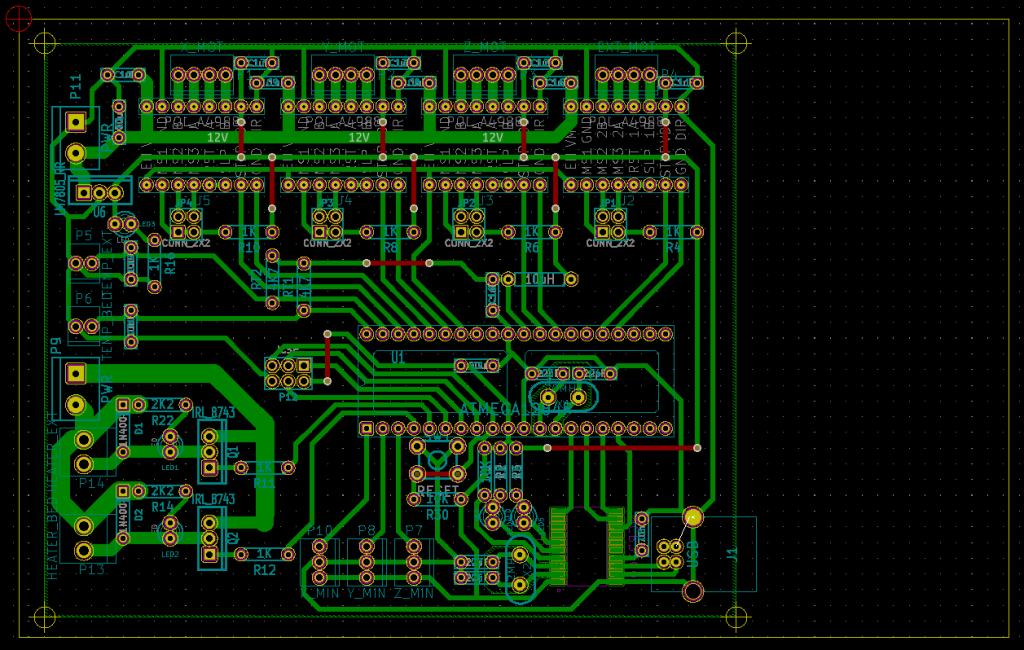

I ported the schematic into KiCad and started laying tracks on the board. Using screw terminals for the Cable/Board connections meant that I did not need to worry overly about the power supply – with only a small amount of work, it should still work with ATX.

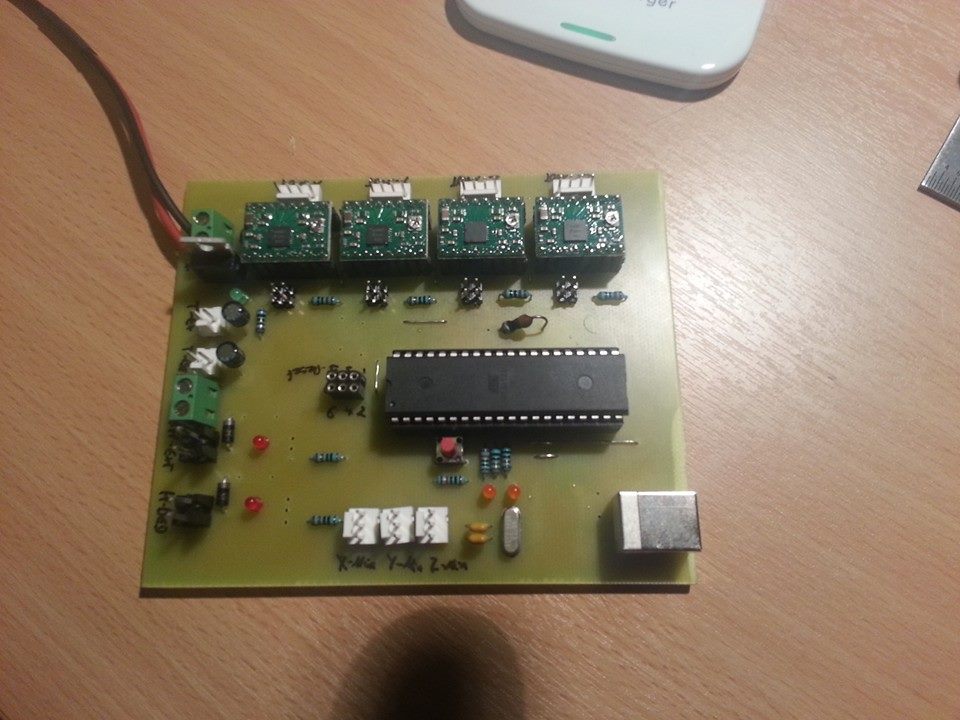

Producing the board was done via a good old lightbox and exposing a pre-coated copper clad single layer board. Etching was done in Ferric-Chloride and then the remaining resist removed with acetone.

Opting for larger than normal traces (30mils – 0.762mm) and very loose design rules gave a much better chance of success for home equipment.

After populating the board and loading up some firmware, calibration could begin

Lessons learnt? Laying out tracks is time consuming and an auto-router may have helped. KiCad helped work based on a single sided board, as I could use the via placements and top/bottom routing for those other traces.

Going through hole in todays world is a bit silly – surface mount components are so much cheaper and it would reduce the amount of drilling required for this. Hand soldering 0805 parts is very much possible (and something I’ve done in other projects…) and the USB/Serial converter chip is an almost exclusively surface mount component.

Would I recommend this path to anyone else? Absolutely – not as a commercial venture, but as a way to produce fairly simple single sided boards for prototypes and one-offs, it’s not too onerous, with only a few chemicals that require some special handling (resist developer, etching chemical), and some care to be taken with the drilling. Carbide drills are not overly expensive, but do require a high speed to be effective, but are very intolerant to flex – drill straight (use a drill press!) and you’ll be fine

Leave a Reply

You must be logged in to post a comment.